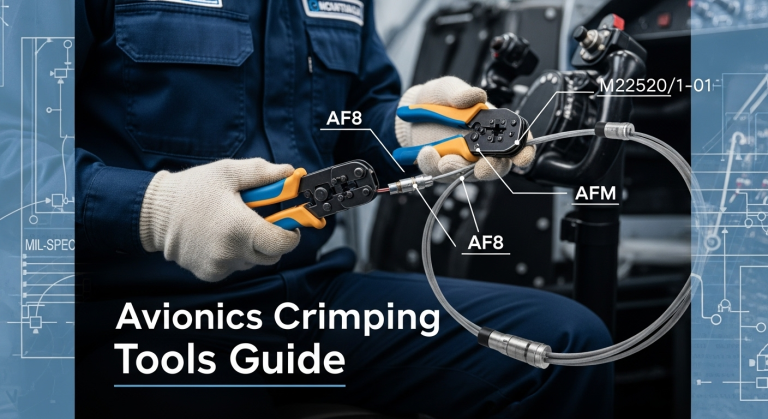

Ensuring Electrical Integrity in Harsh Aerospace Environments

In aerospace environments, maintaining electrical continuity under extreme conditions is critical. This guide covers the types, specifications, and installation best practices of environmental and non-environmental splices used in avionics systems.

Introduction

Maintaining electrical continuity and insulation integrity in aircraft wiring is essential, especially in harsh environments exposed to moisture, vibration, chemicals, and extreme temperatures. Environmental or sealed splices are designed to prevent contamination and ensure reliability, making them crucial for both commercial and military avionics systems.

Environmental or Sealed Splices Overview

Sealed splices are specialized connectors that provide environmental protection to electrical joints. They are primarily used where wiring is exposed to challenging conditions. These splices are built to comply with standards such as SWPM 20-30-12.

Types of Sealed Splices

5.1 Standard Sealed Splices

| Part Number | Color Code | Pin Size | Image |

| D-436-36 | Red | 20 | |

| D-436-37 | Blue | 16 | |

| D-436-38 | Yellow | 12 |

5.2 Shielded Solder Sleeves

| Part Number | Color Code | Pin Size | Image |

| D150-0174 | Red | 20 | |

| D150-0176 | Blue | 16 | |

| D150-0170 | Yellow | 12 | |

| BACS13DP | SIZE:( -1 UP TO -4) |

5.3 Side Entry Wire Insulation Sleeves

BACS13DP Series (sizes -1 through -4) are used for side-entry insulation repair.

Required Tools for Sealed Splices

6.1 Crimping Tools

| Tool Part Number | Use Case | Image |

| GMT-232 or AD-1377 | Crimping environmental splices |

6.2 Ground Block Tools

| Tool Part Number | Use Case | Image |

| LH8 | Contact crimp/removal for ground blocks |

Non-Environmental Splices

Non-environmental splices are used in controlled areas not exposed to harsh elements. They provide basic electrical continuity without environmental sealing.

7.1 Non-Environmental Splice Types

| Part Number | Color Code | Pin Size | Image |

| NAS1388-1 | Red | 22–18 | |

| NAS1388-2 | Blue | 16–14 | |

| NAS1388-3 | Yellow | 12–10 | |

| NAS1388-5 | White | 26–22 |

7.2 Tools for Non-Environmental Splices

| Tool Part Number | Pin Size | Image |

| 59250 | 22–16 | |

| 59275 | 22–14 |

Installation Best Practices

- Use only approved crimping tools and heat guns.

- Strip wires to the correct length (typically 5–6 mm).

- Apply heat evenly, starting from the center to the ends.

- Inspect for proper adhesive flow and seal coverage.

- Perform post-installation pull tests and insulation resistance checks.

Conclusion

In avionics, sealed splices are indispensable for ensuring long-term system integrity in harsh environments. Their proper installation and inspection help maintain airworthiness by protecting against vibration, moisture, and chemical exposure throughout an aircraft’s operational life.