1. Introduction

In avionics systems, ensuring the proper torquing of electrical connectors is vital for maintaining operational reliability and safety. Connectors used in aircraft must handle not only routine electrical loads but also withstand extreme environmental conditions, including vibration, temperature fluctuations, and electromagnetic interference (EMI). Improper torquing, whether excessive or insufficient, can compromise the mechanical and electrical performance of connectors, leading to critical issues such as intermittent connections, signal loss, or total failure. This guide outlines the importance, methods, tools, and best practices required to perform proper connector torquing in avionics environments.

2. Why Torque Matters

- Electrical Continuity: Appropriate torque ensures that contact surfaces within the connector are properly mated, minimizing resistance and maintaining signal integrity. Loose connections increase resistance, which can lead to heat buildup and eventual failure.

- Prevention of Over-tightening: Excessive torque can damage connector threads, deform shells, or crush sealing gaskets, leading to mechanical failure or loss of environmental protection.

- Protection Against Under-torquing: Undertightened connectors may vibrate loose during flight, leading to signal dropout, arcing, or loss of communication. Such issues can have severe implications in safety-critical avionics systems.

- EMI Shielding Integrity: Many connectors include EMI shielding features that rely on precise mechanical engagement. Proper torque ensures these shields maintain continuity and reduce electromagnetic interference.

3. Safety Precautions

3.1 Power Disconnection

Before handling or torquing any electrical connectors, the aircraft’s electrical system must be fully de-energized. Technicians should switch off the relevant circuit breakers (CBs) and verify that no voltage is present using a multimeter or voltage tester. This step prevents electrical shock, short circuits, or equipment damage.

3.2 CB Collar Installation

Installing a circuit breaker collar is a critical safety step. The collar ensures that the breaker remains in the OFF position throughout the maintenance procedure. It also provides a visible indicator to other technicians that work is being performed, thus reducing the risk of accidental re-energization.

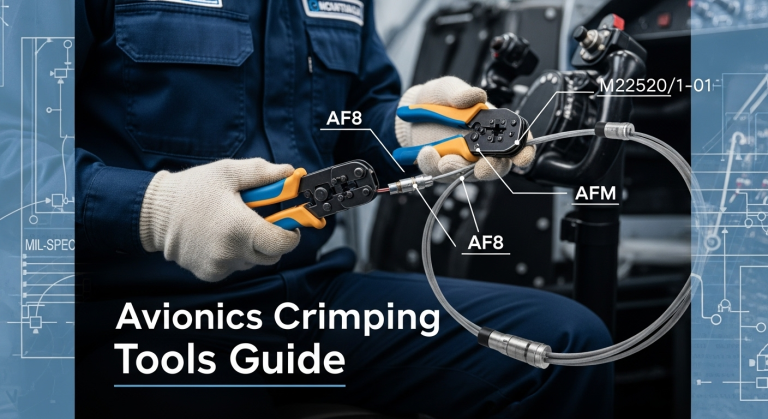

4. Required Tools

| Tool Name/Part No. | Description | Use | Image |

| TG-70 / BT-BS-609 | Strap wrench | Used to hold circular connectors in place without damaging their surfaces. | |

| 586-496 | 3/8” Extension bar | Allows torque to be applied in tight or hard-to-reach locations. | |

| 296050002-1 | CB collar (Skylox) | Prevents accidental re-energization of a circuit during maintenance. | |

| TG-69 / G77015 | Padded connector plier | Used to grip connectors safely without deforming or scratching them. | |

| BT-SJ-468-1 | Replacement pad | Spare pads for the padded plier to ensure continued protection of connector surfaces. |

5. Setting Up the Torque Wrench

- Secure the connector using a strap wrench or padded pliers to prevent rotation and damage.

- Attach the extension bar to the torque wrench to reach the connector if space is constrained.

- Fit the appropriate torque wrench socket to the connector nut or coupling ring.

- Apply torque in accordance with the aircraft OEM or connector manufacturer’s specifications. Ensure the torque wrench is calibrated.

- Once torque is applied, check the alignment and seating of the connector. Ensure locking mechanisms (if present) are engaged properly.

6. Best Practices

- Avoid pliers or adjustable wrenches: These can scratch, crush, or misalign connectors.

- Do not over-tighten: Apply torque precisely according to specifications; even a small overage can deform sensitive components.

- Work in stable temperatures: Torque values can be affected by material expansion or contraction. Avoid extremes.

- Only use anti-seize if OEM-approved: Applying the wrong compound can contaminate electrical paths or alter torque values.

- Always log torque work: Documentation ensures traceability, compliance, and aircraft maintenance continuity.

7. Conclusion

Proper torquing of connectors in avionics systems is a foundational practice that supports electrical reliability, system safety, and mechanical durability. By understanding the purpose behind torque specifications, using the correct tools, and following industry best practices, technicians contribute directly to the airworthiness and mission success of modern aircraft. Adhering to torque standards isn’t just procedural; it’s essential.