In the field of avionics, contact crimping tools are vital for the secure and reliable termination of electrical wires to connector contacts, ensuring electrical continuity, mechanical strength, and long-term durability in demanding aerospace environments.

Contact crimping tools are used to deform a connector contact (pin or socket) around a wire conductor to establish a gas-tight, vibration-resistant mechanical and electrical bond. Proper crimping is essential in avionics to withstand:

- High vibration

- Temperature extremes

- Electromagnetic interference (EMI)

- Moisture and corrosion

All aerospace and military-grade crimping must adhere to MIL-SPEC standards, such as:

- MIL-DTL-22520: The overarching specification for crimping tools and accessories.

- IPC/WHMA-A-620: Industry standard for cable and wire harness assemblies.

Proper calibration, periodic inspection, and test crimps (pull tests) are essential to maintain tool accuracy and compliance.

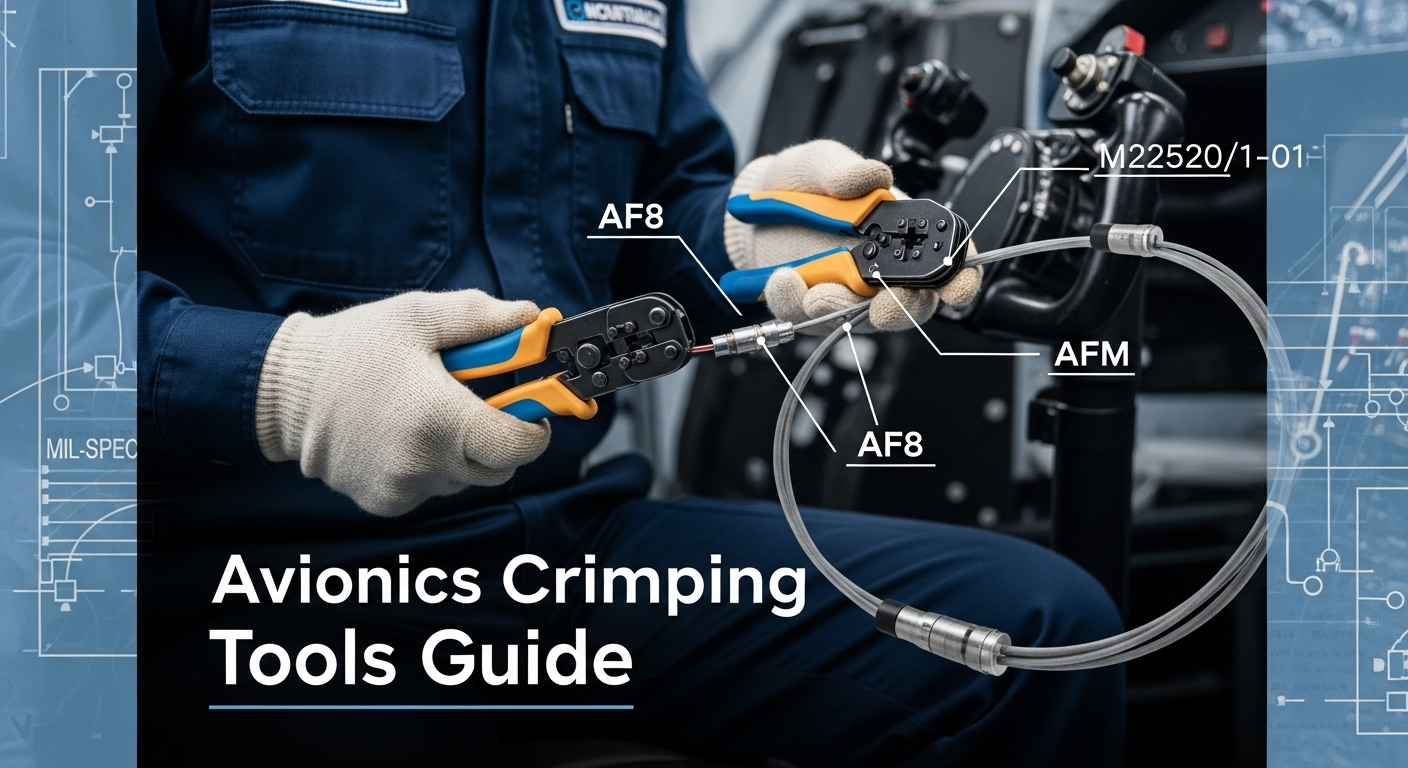

CONTACT CRIMPING TOOLS

| TOOL PART NUMBER | PIN SIZE | IMAGE |

| AF8 OR M22520/1-01 | 12-20 |

BEFORE USING AF8 OR AFM8, MAKE SURE YOU USE GO/NO-GO GAUGE CHECK:

P/N: M22520/3-1 TOOL NAME: GO/NO-GO

| TOOL PART NUMBER | PIN SIZE | IMAGE |

| AFM8 OR M22520/2-01 | 20-32 |

COAX CRIMPING TOOLS: (20-51-00)

| TOOL PART NUMBER | PIN PART NUMBER (TOOL CODE) | IMAGE |

| M22520/5-01HX4 | FROM CONNECTOR PART NUMBER |

NOTE: THE SELECTION COAX CRIMPING OF TOOLS DEPENDS ON THE PIN OR SLEEVE PART NUMBER, USED AS A TOOL CODE.

JACKET REMOVAL TOOLS (20-00-15)

| TOOL PART NUMBER | WIRE TYPE CODE | DESCRIPTION | COLOR CODE | IMAGE |

| 45-401 | REFER SWPM | JACKET REMOVAL | ORANGE | |

| 45-402 | REFER SWPM | JACKET REMOVAL | YELLOW | |

| 45-403 | REFER SWPM | JACKET REMOVAL | PINK | |

| 45-404 | REFER SWPM | JACKET REMOVAL | GREEN |

REFERENCE: FOR 20-00-15

NOTE: THE SELECTION JACKET AND INSULATION REMOVAL OF TOOLS DEPENDS ON WIRE TYPE CODE (WTC).

INSULATION REMOVAL TOOLS

| TOOL PART NUMBER | AWG | WIRE TYPE CODE | DESCRIPTION | COLOR CODE | IMAGE |

| 45-173 ST2222-30 | 10-14 | REFER SWPM | INSULATION REMOVAL | DMC BOEING | |

| 45-174 ST2222-29 | 16-26 | REFER SWPM | INSULATION REMOVAL | DMC BOEING |

Conversion Chart (Military to DMC)

In many aviation maintenance settings, technicians often face the challenge of cross-referencing military part numbers with commercial equivalents, particularly when using tools from manufacturers like Daniels Manufacturing Corporation (DMC).

What is a Conversion Chart?

A conversion chart is a reference tool that maps:

- MIL-SPEC part numbers (e.g., M22520/1-01)

- To their DMC commercial counterparts (e.g., DMC AF8 tool)

This allows avionics personnel to:

- Identify compatible DMC tooling based on the MIL-spec requirement

- Avoid procurement errors

- Maintain traceability for compliance and auditing

Example Conversion Table:

| MIL-SPEC Tool No. | DMC Equivalent | Description |

|---|---|---|

| M22520/1-01 | AF8 | Standard adjustable hand crimper |

| M22520/2-01 | AFM8 | Miniature adjustable hand crimper |

| M22520/7-01 | HX4 | Heavy-duty crimper for coaxial contacts |

| M22520/5-01 | WA22 | Pneumatic crimp tool |

Likewise, positioners and turrets also follow this mapping, for example:

| MIL-SPEC Positioner | DMC P/N | Connector Family |

|---|---|---|

| M22520/1-02 | TH1A | General circular contacts |

| M22520/2-06 | K42 | Size 20 M39029 contacts |

These charts are typically provided in:

- Tooling catalogues

- DMC documentation

- Aerospace wiring standards libraries

To conclude in avionics, precision and repeatability are non-negotiable, contact crimping tools are foundational to these principles. By integrating the correct tools and leveraging conversion charts between MIL-SPEC and DMC, technicians can ensure compatibility, compliance, and consistent quality in aircraft electrical systems. Whether maintaining a military platform or commercial airliner, using approved and calibrated crimp tools in accordance with standards is critical for mission and flight safety.