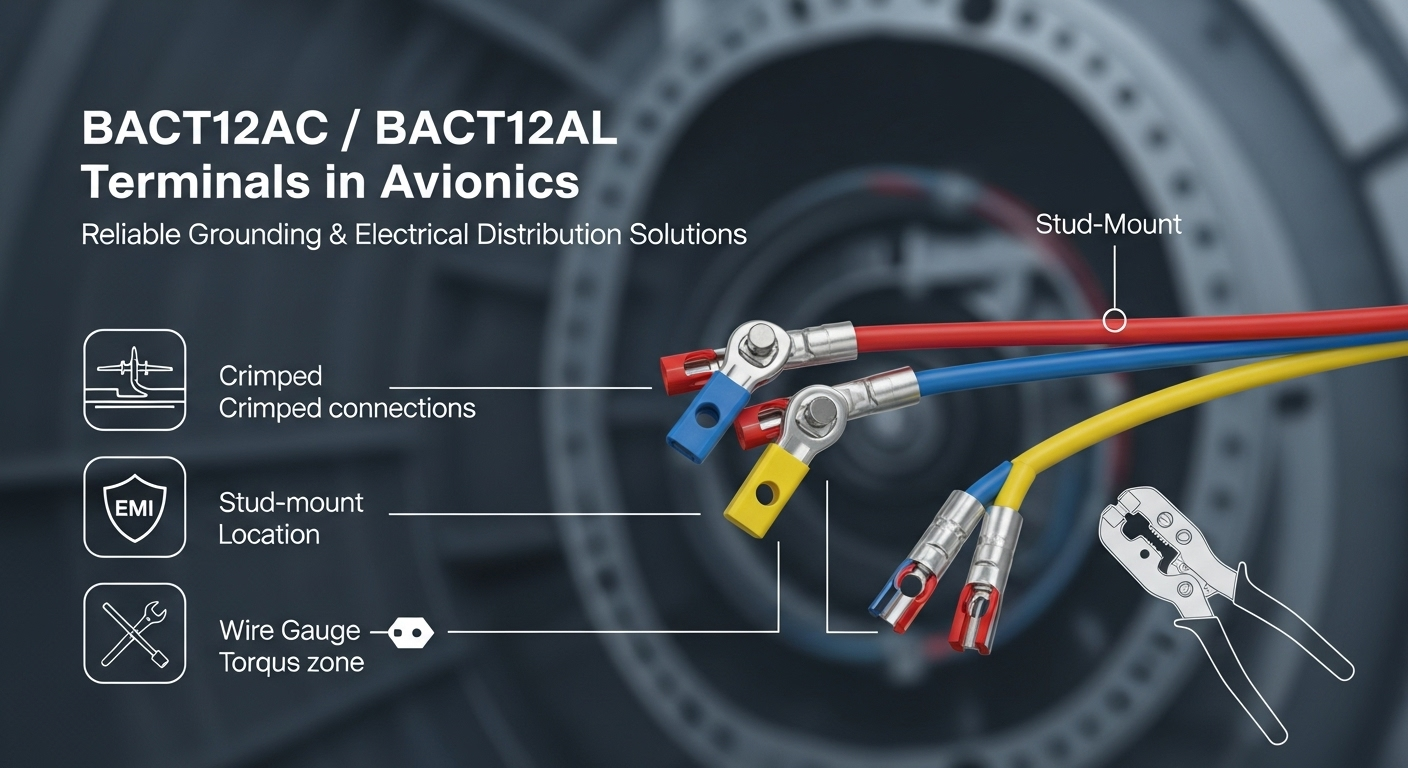

Versatile Grounding and Power Distribution Solutions in Avionics Systems

BACT12AC and BACT12AL general purpose terminals are widely used in avionics for secure grounding and electrical distribution. Designed to meet stringent aerospace standards, they ensure durability, EMI control, and long-term performance. This guide outlines their material specs, part numbers, installation tools, and inspection protocols.

Introduction

General purpose terminals play a crucial role in avionics installations, supporting reliable grounding, bonding, and wire termination. Used extensively in both commercial and military aircraft, these terminals ensure electrical integrity and compliance with aerospace standards such as those established by Boeing (BAC specs).

Terminal Types Overview

4.1 BACT12AC Terminals

- Material: Copper alloy

- Finish: Electro-tinned

- Use Case: General-purpose electrical use

- Environment: Corrosion-resistant areas without environmental sealing

4.2 BACT12AL Terminals

- Material: Aluminum alloy

- Finish: Anodized

- Use Case: Lightweight applications, aluminum wire compatibility

- Environment: Weight-critical zones

Part Numbers and Specifications

5.1 General Purpose Terminals (BACT12AC / BACT12AL)

| Part Number | Wire Size (AWG) | Stud Size | Color Code | Image |

| BACT12AC 45 | 26–24 | 6 | Yellow | |

| BACT12AC 3 | 22–18 | 10 | Red | |

| BACT12AC C8 | 16–14 | 10 | Blue | |

| BACT12AC 12 | 12–10 | 10 | Yellow |

5.2 High-Temperature Nickel Terminals

| Part Number | Wire Size (AWG) | Stud Size |

| BACT12AV012 | 22–18 | 8 |

| BACT12AV014 | 16–14 | 1/4 |

| BACT12AV023 | 12–10 | 10 |

| BACT12M | 22–18 | 8 |

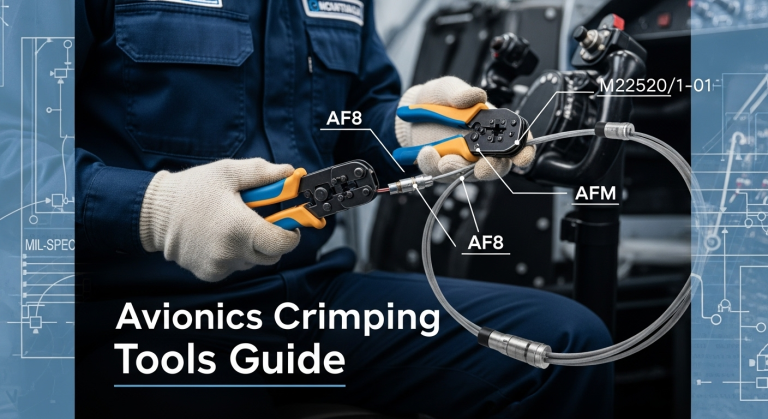

Installation Tools

6.1 Terminal Crimping Tools

| Tool Part Number | Image |

| 59250 | |

| 59275 | |

| 59239 |

Inspection and Maintenance Guidelines

- Visual Inspection: Check for corrosion, insulation damage, and secure fit

- Torque and Fit: Verify fastener torque per OEM specs

- Electrical Test: Ensure ground resistance does not exceed 2.5 milliohms (FAA/EASA)

- No Reuse: Replace terminals if removed or damaged

Conclusion

BACT12AC and BACT12AL terminals are essential components for safe, durable avionics wiring. When installed with the appropriate tools and inspected according to maintenance standards, they contribute significantly to long-term system reliability and airworthiness in aerospace environments.