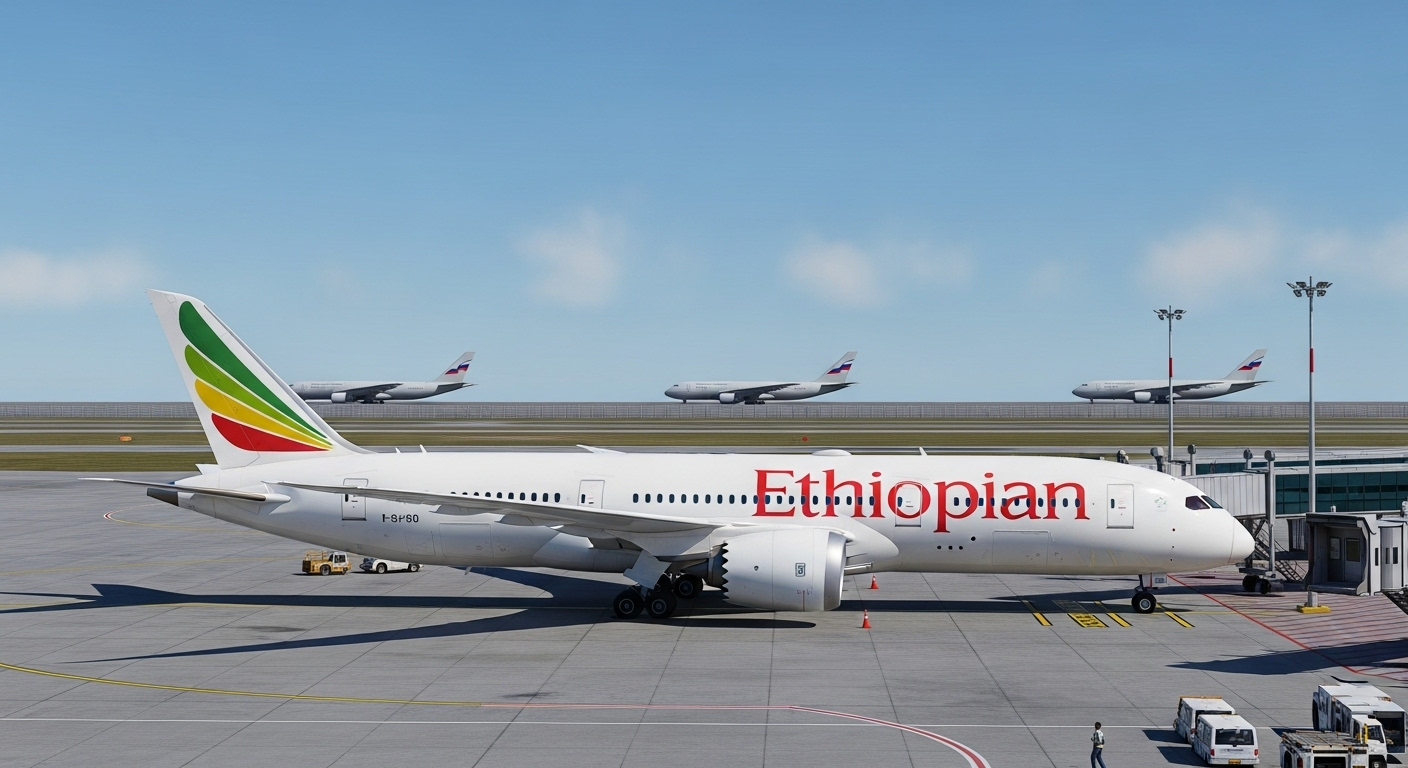

In today’s fast-paced aviation landscape, where every minute on the ground directly impacts operational costs and passenger confidence, line maintenance stands as the unsung hero that ensures aircraft remain safe, reliable, and ready for the skies. Think of it as the aviation equivalent of a high-performance racing pit stop: swift, precise, and mission-critical.

This article delves into the pivotal role of line maintenance and its evolution with the advent of dedicated Light Maintenance Support. Drawing on two decades of frontline expertise, we’ll explore the foundational tasks that keep aircraft airborne, the regulatory nuances outlined in EASA Part-145, AMC 145.A.10, and the strategic integration of support structures that elevate maintenance from mere necessity to competitive advantage. Join us as we unpack how refining these processes equips airlines to thrive, regulatory compliance, turnaround speed, and operational resilience all included.

What Is Line Maintenance, And Why It’s Essential

Line maintenance refers to routine, rapid-turnaround aircraft servicing conducted at the gate or on the ramp between flights, designed to confirm safety, airworthiness, and readiness for the next operation. Tasks typically include visual inspections, fluid checks, minor repairs, tire changes, and other quick interventions that avoid prolonged downtime, unlike base or heavy maintenance operations.

Under EASA Part-145, AMC 145.A.10, line maintenance comprises activities performed before flight to ensure the aircraft is fit for its intended journey. These may include:

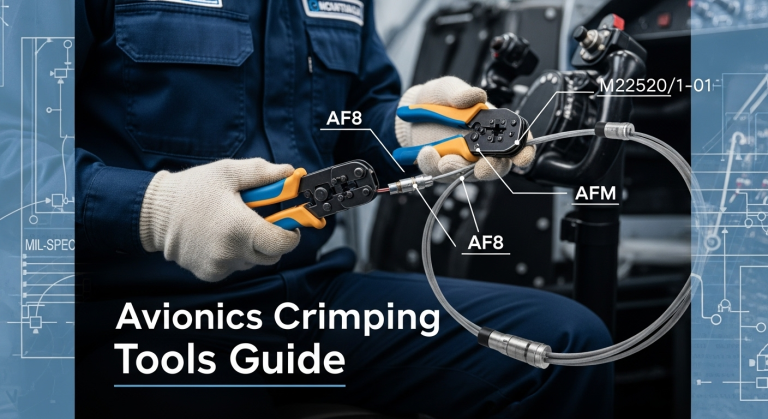

- Troubleshooting and defect rectification.

- Component replacements, including engines or propellers, using external test equipment, if needed.

- Scheduled maintenance or visual inspections that uncover obvious failures without requiring in-depth dismantling.

- Minor repairs or modifications executable via simple means and accessible through quick-opening panels.

The regulation intentionally uses the term may, acknowledging flexibility in classification. In special or temporary cases, such as compliance with Airworthiness Directives (ADs) or Service Bulletins (SBs), the Quality Manager may permit line maintenance organizations to execute base maintenance tasks, provided all regulatory requirements are met. Tasks outside this scope, however, should be classified and conducted as Base Maintenance.

Why Line Maintenance Matters

- Operational Safety and Reliability: Line maintenance is the first line of defense, detecting and managing potential faults before they escalate into safety issues or flight delays.

- Efficiency and On-Time Performance: By enabling quick turnarounds, airlines maintain punctual schedules and minimize disruptions, boosting operational performance.

- Cost Avoidance: Addressing minor issues early helps avert costly repairs and extended ground time.

- Airworthiness and Compliance: Routine pre-flight checks enforce compliance with industry standards and uphold passenger confidence.

Line Maintenance in the Real World

Industry professionals describe the line maintenance environment as unpredictable, “hours of boredom, minutes of chaos,” depending entirely on what the aircraft brings in. Others liken it to being part of a “Nascar pit crew”, fast-paced, thrilling, and richly educational.

Yet it’s not for the faint-hearted. When problems arise, like tire and brake changes under tight turnaround constraints, the pressure is real.

The Role of Light Maintenance / Line Maintenance Support

As airline operations scale up, so does the complexity of line maintenance. Managing more aircraft across multiple stations, varying climates, and heightened passenger demand requires a robust support structure:

Light Maintenance Support extends capabilities beyond routine line operations, primarily focusing on:

- Scheduled works, such as Aircraft Service Checks as part of planned maintenance programs.

- Unscheduled tasks, including APU changes, thrust reverser replacements, inlet cowl adjustments, fuel tank entries, and other complex activities demanding specialized skills and extra manpower.

This support team works closely with Maintenance Control Centers (MCC/MOCC), manufacturers, and external vendors to expedite defect rectification, monitor long-standing issues, and manage MEL (Minimum Equipment List) and CDL (Configuration Deviation List) compliance.

Operating 24/7, the Light Maintenance Support team is typically composed of B1/B2-certified engineers and technicians with cross-disciplinary experience in line, base, and heavy maintenance.

Avoiding Common Pitfalls

Enhancing line maintenance through Light Maintenance Support also addresses several recurrent issues:

- Documentation Gaps: Incomplete logs, missing inspection records, or poor compliance documentation can jeopardize safety, audit readiness, and operational continuity.

- Skipping Preventive Maintenance: Ignoring routine servicing in favor of immediate tasks might seem efficient, but it increases the risk of escalated issues, grounded aircraft, and reduced asset longevity.

- Lack of Regular Audits: Audits aren’t mere formalities, they validate processes, safeguard safety, and ensure transparency across maintenance activities.

Toward a Smarter Future in Line Maintenance

As airlines grow, line maintenance operations must evolve, from station-based, reactive models to integrated, data-driven, and standardized systems. That transition requires:

- Seamless coordination between MCCs and line engineers.

- Skilled workforce and nimble logistics.

- Rigorous compliance oversight.

- Smart use of technology to manage data, track airworthiness in real-time, and optimize task alignment.

Integrating Light Maintenance Support into the broader maintenance strategy equips airlines to stay agile, minimize downtime, and uphold uncompromising safety and reliability.

In the evolving world of aviation, line maintenance stands as the indispensable heartbeat of daily operations, where precision, speed, and safety converge in every gate-side task. When paired with specialized Light Maintenance Support, airlines unlock a resilience that transcends traditional boundaries, ensuring seamless aircraft readiness, regulatory compliance, and operational agility.

From routine visual checks to handling complex AOG scenarios, these maintenance layers form the backbone of airworthiness and airline reliability. The real magic lies in anticipating challenges before they arise: embracing smart documentation, preventive strategies, and robust audit systems to mitigate risk and avoid common missteps.

As the aviation landscape grows more complex, driven by expanding fleet footprints, diverse operating environments, and data-intensive workflows, the strategic value of integrated, tech-enabled maintenance only intensifies. By adopting a coordinated, streamlined approach, airlines not only safeguard safety and minimize disruptions but also enhance profitability, customer trust, and brand reputation.

Ultimately, the future of line maintenance isn’t about reacting faster, it’s about building smarter, more adaptive systems that keep aircraft, orchestrated, airworthy, and always ready to fly.