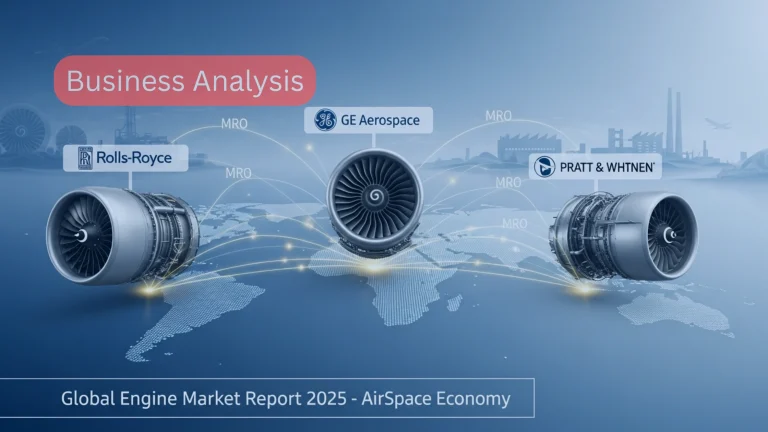

Maintenance, Repair, and Overhaul (MRO) is a vital pillar of the aviation industry, ensuring aircraft remain airworthy, reliable, and cost-efficient. As the global aviation sector grows, the importance of specialized MRO models—each tailored to specific operational demands—has never been greater. From in-house airline hangars to agile independent repair shops, MRO strategies vary widely depending on fleet size, operational scope, and business needs. This article breaks down the major types of MRO business models in aviation and how they each contribute to fleet performance and long-term sustainability.

1. Commercial Airline-Owned MROs

Major airlines often maintain their own in-house MRO departments near hub airports. These facilities handle everything from routine inspections to heavy maintenance checks (D-checks).

Benefits:

- Reduced downtime through scheduling integration

- Greater quality control and procedural alignment

- Cost savings on logistics and reduced reliance on third parties

In-house MROs enable airlines to manage their fleets efficiently while minimizing service disruption and enhancing aircraft utilization.

2. Regional Airlines and Air Taxi Operations

Smaller regional carriers and air taxi services typically operate decentralized networks. Their MRO strategies are often shaped by location-specific logistics, labor availability, and budget constraints.

Common Approaches:

- Outsourcing to third-party MRO providers in key regions

- Establishing maintenance partnerships in areas with limited technician availability

- Prioritizing quick turnaround times and flexible scheduling

While some larger regional operators may invest in their own MRO teams, many rely on trusted local providers to maintain service reliability.

3. In-House Corporate Aviation Maintenance

Corporate flight departments often fly business jets that do not require high-frequency maintenance. Maintenance is typically managed under manufacturer warranty programs or outsourced to OEM-authorized service centers.

Why In-House MRO is Rare:

- Limited aircraft volume

- High reliance on OEM support plans

- Emphasis on convenience and compliance over scale

However, large corporations with extensive fleets may opt for limited in-house maintenance to support frequent operations.

4. Independent Repair Stations

Independent MRO facilities serve a wide range of customers, offering specialized services in niche areas such as avionics, wheels and brakes, interiors, and more.

Key Advantages:

- Focused expertise in specific systems

- Competitive pricing compared to OEMs

- Capacity to serve regional, charter, and legacy fleets

These stations are especially valuable for operators needing flexible, cost-effective maintenance without large-scale infrastructure.

5. Fixed-Base Operators (FBOs)

FBOs often operate at smaller general aviation airports and provide essential line and light base maintenance services for private and charter operators.

Typical FBO Maintenance Services:

- Daily checks and turnarounds

- Light troubleshooting and component replacement

- Cabin and interior work

- SB/AD/EO compliance

FBOs play a crucial role in supporting GA and business aviation segments with efficient ground handling and technical assistance.

Conclusion

The aviation maintenance landscape is highly diverse, with each MRO model tailored to specific market needs. Commercial carriers rely on integrated solutions, while smaller and regional operators benefit from flexible third-party partnerships.

Understanding which MRO business model fits your operation is key to maintaining fleet readiness, controlling costs, and staying compliant with evolving aviation regulations.

As demand for reliable MRO services continues to grow globally, stakeholders across the aviation ecosystem must assess, invest, and adapt their maintenance strategies for long-term success.