The Rear Release Terminal Module (RRTM) is integral to the performance and maintainability of modern avionics systems. It enables safe, efficient, and serviceable electrical contact handling, especially suited for high-reliability aerospace environments. This guide provides an overview of RRTM’s features, specifications, and best practices for technicians.

Introduction

The Rear Release Terminal Module (RRTM) is a vital component in aircraft avionics systems. It ensures reliability, ease of maintenance, and efficient wire termination within circular or rectangular multi-pin connectors. This guide outlines its functionality, usage, and best practices.

Functional Overview of RRTM

RRTMs house crimped electrical contacts, securely retaining them within the connector body. Unlike front-release connectors that operate from the contact interface, rear-release systems operate from the wiring side. This configuration enhances maintainability and reduces the risk of wire damage.

Key Features

- Contact Retention Mechanism

- Ease of Maintenance

- Insertion/Extraction Tool Compatibility

- High-Density Capability

- Environmental and EMI Protection

RRTM Part Numbers and Specifications

A. Standard RRTM Modules

| Part Number | Pin size | Type | Contact part number | Image |

| S280w555-102 | 16 | (X) P | M39029/1-101 | |

| S280w555-104 | 16 | (Y) Q | M39029/1-101 | |

| S280w555-108 | 16 | (Z) U | M39029/1-101 | |

| S280w555-203 | 14 | (V ) V | M39029/1-102 | |

| S280w555-206 | 14 | (W) W | M39029/1-102 |

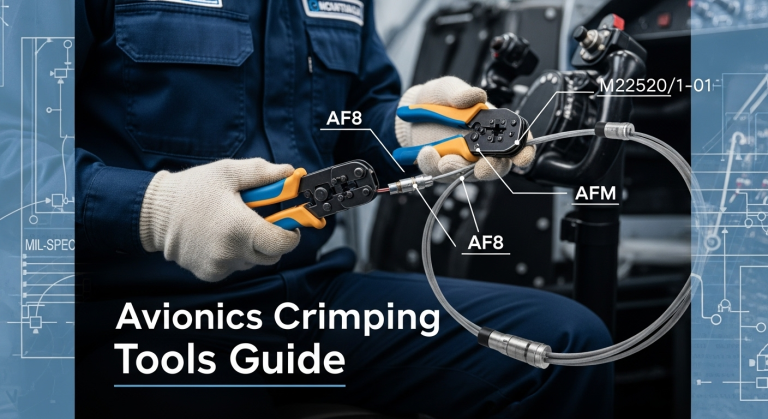

NOTE: All pins are crimped using AF8 and AFM8 and all pins are removed by a rear removal plastic tool as required.

B. High-Density RRTM Modules

| Part Number | Pin size | Type | Contact part number | Image | Contact removal | Crimping |

| BACM15C3A | 16 | X | M39029/11-145 | M81969/1-02 OR DHK21 | AF8 OR AFM8 | |

| BACM15C3B | 16 | Y | M39029/11-145 | M81969/1-02 OR DHK21 | AF8 OR AFM8 | |

| BACM15C3C | 16 | Z | M39029/11-145 | M81969/1-02 OR DHK21 | AF8 OR AFM8 | |

| BACM15C1B | G | BACC47DE | DHK21 | LH8 |

Repair Guidance

7.1 Repair in Unpressurized Areas

Repairs are performed using sealed configurations per SWPM 20-10-13 to prevent environmental factors like moisture or debris from affecting the wiring integrity.

7.2 Repair in Pressurized Areas

Use sealed configurations wherever possible. If not feasible, non-environmental splices that maintain electrical and mechanical integrity are acceptable.

7.3 Minor Damage Repairs

Use side-entry sleeves (BACS13DP-1 through -4) to restore and insulate damaged wires.

Technician Best Practices

- Always use OEM-specified tools and adhere to torque/insertion standards.

- Perform a ‘tug test’ to verify contact retention.

- Avoid excessive bending of wires near the module.

- Document all contact insertions/removals in maintenance logs.

Rear Release Terminal Modules (RRTMs) are foundational to the performance and serviceability of aircraft electrical systems. Their rear-serviceable design allows technicians to perform maintenance with minimal disruption, increasing system longevity and ensuring operational airworthiness.